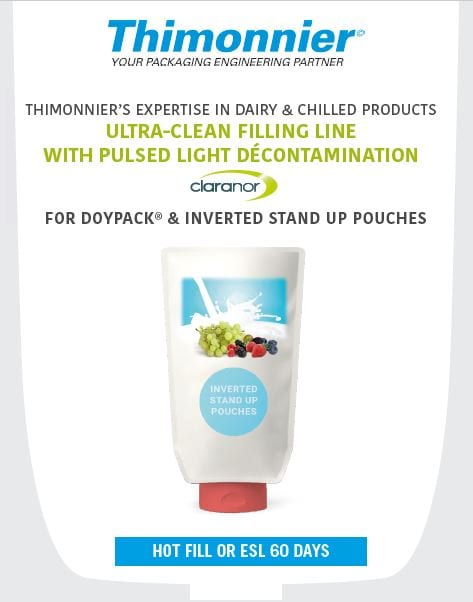

Ultra-clean filling line with Claranor Pulsed light decontamination

The Thimonnier SF102 is a filling-capping line wthout chemical for Doypacks and inverted pouches.

Modular, compact and adapted to high speed

The use of preformed pouch with filling by the spout offers the producers a great flexibility:

- position of the cap, shape and volume of the pouch,

- format change without mechanical adjustment,

- 240 pouches per minute in 3 lines version.

Extended shelf life, thanks to pulsed light decontamination and sterile air conditioning

Thanks to spout and cap decontamination with pulsed light from Claranor, sanitation of the dosing system and filling under positive pressure of aseptic air, ultra-clean SF machine allows the filling of fresh or pasteurized dairy products with a shelf life up to 60 days depending on the products.