CRAFT BEER PACKAGING DECONTAMINATION BY PULSED LIGHT

Craft beer market

The craft beer market reached a value of US$ 103.85bn in 2021, and it is expected a huge growth in the coming years to reach a value of US$ 200.62bn by 2027. Almost all countries are concerned. The market drivers are the vast variety of flavors and styles of craft beer, their high quality (Source: Imarc 2021).

Contamination risks

Process hygiene plays a major role in the production of high-quality beer. The filling process is considered to be the highest potential risk of secondary contamination of the product. And cross-contamination could occur due to the packaging.

Pasteurization protects those products from microbiological issues but alters the organoleptic properties of the product and generates significant energy costs. So, craft beers are often unpasteurized and therefore are vulnerable to microbiological contamination.

Thus, packaging decontamination is a way to reduce microbiological contamination.

Aluminum cans for premium craft beers

Among the packaging option, aluminum can is gaining market shares:

Aluminum cans are sustainable, recyclable indefinitely, and much lighter than bottles to transport. They offer a lower carbon footprint, safe from light, they avoid beer light damage. Moreover, tightly sealed they prevent oxidation. Plus, they are more convenient than glass bottles and are allowed in many places where bottles are not permitted.

Pasteurization is energy consuming and chemical treatment of aluminum can is not an optimal solution

- It uses a lot of water and energy,

- Alters the foaming agents

- And chemical residues could alter the beer’s organoleptic quality.

Pulsed Light is an innovative and efficient packaging decontamination solution that helps in preventing those risks in unpasteurized canned beer.

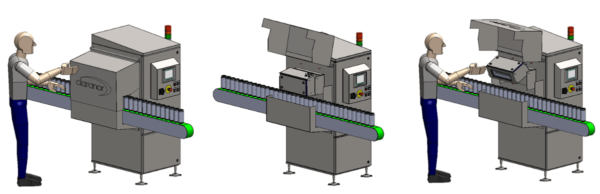

Claranor Pulsed Light for metal cans and lids

90% of the contamination is on the metal can, 10% on the can lid. This is why Claranor has designed compact and cost-efficient equipment for decontamination by Pulsed Light of the whole internal surface of the metal can.

BENEFITS compared to chemical treatment or pasteurization

- Compact up to 10 times more compact (L 1000 x W 800 x H 1900 mm)

- Reduced operating costs

- Instant treatment

- Reliability: proven and same level of efficiency on each pack

- Energy sobriety

- Carbon footprint reduction

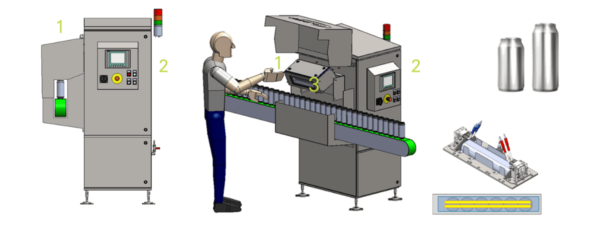

Claranor equipment component

1 – OPTICAL CABINET PROTECTING THE OPTICAL CAVITY

- In-line integration

- Cleanable

2 – ELECTRONIC BAY

- Power supply

- HMI to pilot the optical cabinet

3 – OPTICAL CAVITY

- Xenon lamp with reflector

- Example of treatment by 6 cans

Alu can decontamination by Pulsed Light

FEATURES

- Immediate availability, no preheating, instant treatment

- Allows the treatment of each pack and makes it easy the management of the production lines: stops and restarts

- Athermal, no heat emission in the working environment

- Water/Water thermal regulation to control the lamp and the reflector, in a separate enclosure, within the cabinet

Air-cooled regulation, air conditioning - 3 log reduction on Aspergillus brasiliensis