Time to adopt Claranor Pulsed Light decontamination on your filling line!

Claranor Pulsed Light will be present at Anuga FoodTec, gathering the food and beverage industry, in Cologne from April 26 – 29,2022.

On this occasion, we will have the opportunity to present our packaging decontamination solutions as well as our new and innovative partnerships in these markets!

Anna, Christophe, Benjamin, and Anthony will be pleased to welcome you!

Hall 7.1, stand C098

Innovative partnerships for efficient industrial solutions!

Claranor and Primoreels join their forces to offer a lidding system that saves on packaging and makes decontamination safer and easier.

Designed to facilitate line renovations, the benefits for manufacturers are numerous:

- Productivity gains,

- Qualitative lids, recyclable with the cup!

- Significant reduction in packaging and over-packaging,

- Improved hygiene and food safety

On this last point, Primoreels offers its customers a turnkey solution. By integrating natively the Claranor Pulsed Light on its lids sealing machine, they have designed an optimal solution for the dairy and plant-based milk industries to protect their products against microbiological contamination by moulds.

Economical and ecological, the equipment will be presented as a preview during the exhibition.

Henrik Salhberg, Primoreels Managing Director, will be pleased to discuss your project and provide you with all technical details on this performing innovation already adopted by major dairy manufacturers.

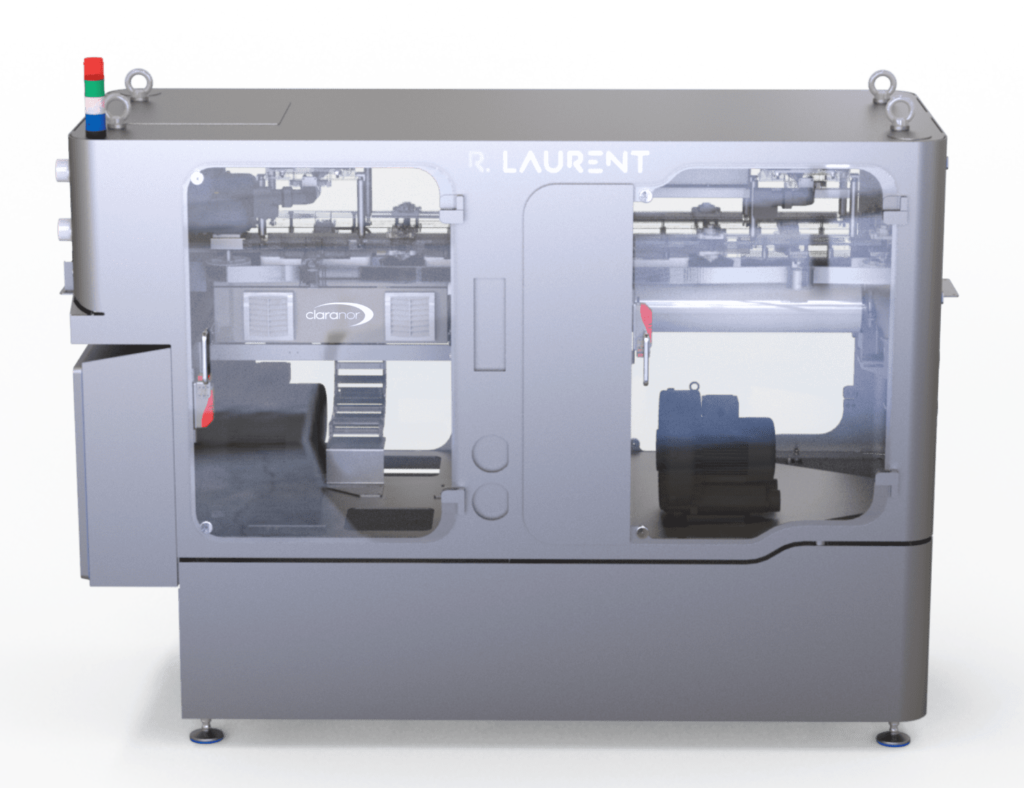

R. Laurent, packaging equipment manufacturer, a key player in the infant milk industry, natively integrates Claranor decontamination solutions.

The aim of this partnership is, on the one hand, to offer infant milk producers a simple and effective global solution to decontaminate, handle, and ensure the fitting of all types of infant milk closures (with or without a scoop cap). And on the other hand, to provide an efficient solution that enables infant formula producers to meet the new specifications, which are increasingly demanding in terms of safety and sanitary quality, particularly for the export to dedicated countries such as China.

Successful partnership with Thimonnier for Doypack® packaging of dairy products!

The Thimonnier SF102 Ultra Clean is a filling-capping machine for fresh and pasteurized dairy products. The use of pre-formed pouches with filling through the cap offers manufacturers great flexibility. Claranor technology is integrated into the line, with two compact modules that provide pulsed light decontamination of the spout and cap, without the use of chemicals and with very low energy consumption. Claranor packaging decontamination and sterile air ensure enhanced food safety and longer shelf life, from 10 to 60 days depending on the product.

The first line is currently being commissioned by one of the largest contract packaging companies.

The customer’s requirement was to find an alternative to the purchase of an aseptic line, which is expensive and constraining while benefiting from the advantages of an ultra-clean filling.

The filling is done cold, to protect the organoleptic qualities of the product.

Moreover, decontamination was required without chemicals and under sterile air, to respect the integrity of the product and avoid all risks of chemical residues.

For more information on our collaboration, meet our team and visit Thimonnier booth Hall 8.1, E040g-F041g!

Successful partnership dedicated to the energy drink market with Aptar

Aptar, the world leader in dispensing systems industry, has been working with Claranor since 2012 to evaluate the performance of pulsed light sterilization on their innovative closures: sport closures, scoop closures for infant milk, etc. Together we have developed a solution to decontaminate the dead volume in sport closures.

The Aptar’Uno sport closure translucent version decontaminated by the FULLCAP® pulsed light treatment offers a chemical-free aseptic sterilization process well adapted to preservative-free and sensitive beverages such as energy drinks, sports and performance drinks, fortified fruit drinks, and enhanced water.

Suitable for existing or new line, Uno sport cap with FULLCAP treatment offers your customer convenience and aseptic level.

With low energy and no water consumption, it is an economic way to upgrade your filling-line.

Book your slot to discuss with Aptar and Claranor teams!

Our new collaboration with Synerlink

Synerlink, is a trusted supplier of in-line filling technology for rigid packaging of dairy products and other food and beverages, as well as a leader in the design and manufacture of state-of-the-art integrated packaging lines for ultra-clean, extended shelf-life and aseptic products.

To be revealed in preview during Anuga FoodTec, our collaboration on Synerlink’s next-generation Flexible Filling Machine!

Happy to show you this brand-new innovation!

To find out more, make an appointment with our team !