Pulsed innovations

for the decontamination of lids, caps, metal cans or aluminum cans and can-ends and refillable bottles

Claranor’s team of experts is pleased to present its latest equipment dedicated to the beverage, dairy and cosmetic markets

at the Pack Expo in Las Vegas from 27 to 29 September 2021

Anthony, Christophe, John, and Henrik will welcome you on our stand where you will be able to discover our packaging sterilization machines using Pulsed Light which reconcile ecology and economy. Four innovative solutions to discover

stand SU7157

Sterilisers that adapt to market trends

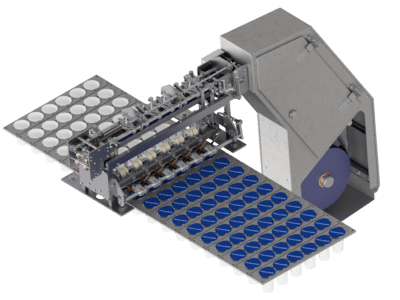

PRIMOREELS® and CLARANOR: THE PERFECT “PACKAGING and STERILIZATION” MATCH

Primoreels is a manufacturer of lids for the food industry and more specifically for the dairy, water and juice industries. It offers an innovative concept that appeals to the largest producers and manufacturers of dairy products.

In addition to supplying BRC-certified lids since 2017, it offers them in rolls of lids in order to limit packaging losses during cutting. This allows for a significant reduction in the carbon footprint.

Presented as a preview during this Pack Expo the collaboration between Claranor and Primoreels, consists of integrating Claranor equipment directly into Primoreels equipment. This equipment will decontaminate the Primoreels by pulsed light before they are applied to the cups.

Instantaneous and non-thermal, the Claranor solution allows the sterilization of all types of lids and even the thinnest films. The direct integration into the Primoreels provides producers with a turnkey solution to meet product quality protection requirements while greatly optimizing productivity and improving the carbon footprint.

FULLCAP®

Also to be discovered on our stand, FULLCAP®, a pulsed light sterilization equipment allowing the decontamination of all the faces of the cap, inside and outside, offering the possibility of extending the shelf life of drinks and liquid dairy products (>90 days). It is a compact and economical alternative to the H202 tunnel. With a speed of up to 60,000 bph, the FULLCAP® solution can be integrated into sensitive refrigerated product lines or even into acid aseptic lines.

To illustrate this innovation, the collaboration with the closure manufacturer Silgan. On the stand, you will find a presentation of the microbiological results and advantages of this FULLCAP® sterilization without chemicals of Silgan 38 mm VSI and DBJ plastic closures for hot filling or ESL 120 days.

METAL or ALU CANS and CAN ENDS

Also on display on the booth are our microbiological decontaminating solutions for the metal or aluminum cans, lids and can-ends.

Our standard or customized equipment can be adapted to the needs and requirements of equipment manufacturers or industrialists.

- Output: 400 cans/minute to 1200 cans/minute

- Dry and athermal process

- No risk of chemical residues

- Compact: 1 to 2 m

These sterilization solutions meet the needs of food and beverages industry manufacturers for liquid products such as sweetened condensed milk, non-alcoholic beer, sports drinks but also for dry products such as powdered infant milk.

STE’REFILL, STERILISATION SOLUTION DEDICATED TO RESPONSIBLE BEAUTY

Finally, visitors will be able to discover Ste’Refill, a patented module for decontaminating bottles by pulsed light, which are to be refilled in a refill station. Designed in partnership with L’Occitane and installed in JeanBouteille refill furniture, Ste’refill is being rolled out internationally! Find more information

Indeed, the washing protocols ensure the cleanliness of the bottle but not its disinfection; to avoid any development of bacteria and/or moulds, it is necessary to decontaminate the bottle.

The Claranor concept ensures the destruction of surface micro-organisms by means of intense light flashes.

It is a simple to use, compact, chemical-free solution that preserves the quality of the product.