Advanced packaging decontamination at Brau Beviale 2024,

DISCOVER ON OUR BOOTH OUR DECONTAMINATING EQUIPMENT

A range of cap sterilizers

To meet the needs of manufacturers, Claranor has designed a range of 3 cap decontamination machines. These solutions are compact, efficient and, above all, easy to integrate into a filling line.

- INNCAP ESSENTIAL

An economical solution, ideal for low- to medium-speed lines, with a capacity of up to 18,000 bottles per hour. It offers producers of slower-filling lines the efficiency and low operating costs of Claranor’s pulsed light technology, outperforming UV and reducing total cost of ownership (TCO).

- INNCAP EVOLUTION and HISPEED

Claranor Ultra-clean cap decontamination equipment is designed for high-speed lines, reaching up to 100,000 bottles per hour. Capable of handling all types and sizes of closures, it is unique on the market to offer such efficiency at this speed.

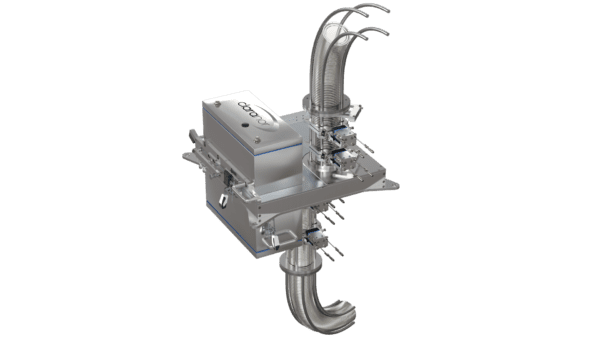

- FULLCAP

Ideal for sports and flat caps, this high-speed solution decontaminates the inner and outer surfaces of caps at up to 120,000 bottles per hour depending on the level of decontamination requested. It guarantees an extended shelf-life of over 60 days (ESL > 60 days). Compact and economical, it is an excellent alternative to hydrogen peroxide (H2O2) tunnels, suitable for both the most sensitive refrigerated products and acidic aseptic applications.

UV MP innovative solution for cap decontamination

Discover our new medium-pressure UV decontamination solution for caps in partnership with DR. Fischer.

Pulsed light decontamination of preform and bottleneck

Dedicated to ESL 30 days, it achieves a decontamination of 3 log reduction on Aspergillus brasiliensis on the neck of the preform or the bottle.

The preform treatment is done before the oven and/or bottleneck before filling. It is an efficient alternative to chemical disinfection.

Claranor sterilization unit is integrated:

- upstream of the blowing step for the preform neck, into the preform descent chute,

- on the conveyor upstream of the filler for the bottleneck.

The speed rate of the machine is up to 100,000 bph.

Pulsed light decontamination of beverage cans

- CAN AND CAN END: Pulsed-light decontamination of the internal surfaces of alu or metal cans and can ends. Sterilization takes place before filling and sealing the lid. This solution is suitable for the Ultra-Clean line without a pasteurization tunnel.

- Lid: pulsed light decontamination of both sides of the lid: the surface in contact with the product or in contact with the aluminium lid, to avoid any risk of recontamination when re-staking.

Our team will be pleased to welcome you to our stand.

BRAU-Beviale is one of the most important European trade fairs for the production and marketing of beers and drinks. An unmissable event for Claranor for several years. More information on the 2024 edition.

Find out more about our decontamination solutions from November 26 to 28 at Brau Beviale 2024!

Benjamin GUERIN

bguerin@claranor.com

Area Sales Manager

Anna MOUTIER

amoutier@claranor.com

Area Sales Manager

Christophe RIEDEL

criedel@claranor.com

CEO