Discover the power of pulsed light and UV at PACK EXPO Chicago 2024!

Claranor is pleased to announce its participation in PACK EXPO Chicago 2024, from November 3rd to 6th. Join us at Booth N5972 to experience proven solutions in chemical-free packaging decontamination! In collaboration with Industrial Machining Services (IMS), Claranor will showcase equipment of some of the most efficient and sustainable packaging decontamination solutions available today. This is a must-attend event for professionals in the beverage, dairy, plant-based, and sauces industries who are looking to improve their processes with eco-friendly technology.

Why visit Claranor at PACK EXPO 2024?

At the Claranor booth, you’ll have the opportunity to discover three powerful machines, each engineered to meet the needs of high-speed, high-efficiency packaging lines.

CLARANOR INNCAP EVOLUTION: ULTRA-CLEAN CAP STERILIZATION

One of the highlights of our booth will be the Claranor Inncap Evolution, an ultra-clean cap decontamination machine that’s designed for high-speed beverage lines. With the ability to process up to 100,000 bottles per hour, this machine is engineered for unmatched efficiency and flexibility.

The Inncap Evolution can handle all types and sizes of closures, making it a versatile solution for a variety of industries, from dairy to plant-based beverages. What makes this machine stand out is its ability to achieve high-speed decontamination without sacrificing sustainability. By using Pulsed Light technology, it ensures a chemical-free process with no water usage and minimal energy consumption.

If you’re in the beverage or liquid dairy industry and are looking for ways to protect your products from contamination the Inncap Evolution is a game-changer

CUP DECONTAMINATION MACHINE: FOR DAIRY, SAUCES, AND MORE

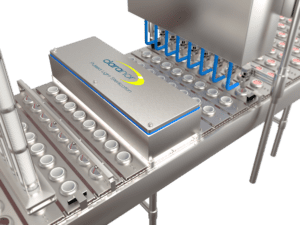

Another must-see at our booth is the Claranor cup decontamination machine, specifically designed for dairy and sauces filling lines. The decontamination of cups in these industries is absolutely critical to avoid cross-contamination and ensure product shelf life. Dairy and plant-based products, in particular, are highly sensitive to microbial contamination, especially from molds, which can significantly impact product quality and safety.

The Claranor cup decontamination machine uses Pulsed Light technology to provide a high level of decontamination, effectively eliminating microorganisms such as mold on the packaging.

This technology operates by delivering high-power light flashes across a wide spectrum of wavelengths, which efficiently destroy contaminants without the need for chemicals or water.

Not only is this machine incredibly effective at decontamination, but it also offers major sustainability benefits. The instant treatment provided by Pulsed Light requires no water and no chemicals, making it a cost-effective and eco-friendly solution. With very low energy consumption, the Claranor Cup Decontamination Machine is an ideal choice for companies looking to reduce their environmental footprint while maintaining the highest standards of product quality.

INTRODUCING UV MIDDLE-PRESSURE DECONTAMINATION: A U.S. FIRST!

For the first time ever in the United States, Claranor will also display a UV middle-pressure decontamination module at PACK EXPO 2024. This technology offers in a complementary solution packaging decontamination, to our Pulsed Light machines.

By integrating these two technologies, we offer a comprehensive decontamination solution that meets the diverse needs of industries such as beverages, dairy, and plant-based products. Our engineers will be available to provide detailed explanations and answer any questions you may have about how these systems can be implemented on your production line.

Meet our engineers and explore chemical-free, sustainable packaging solutions

Take the opportunity to engage directly with our team of engineers and technical experts. Whether you’re looking to improve the hygiene of your packaging process or seeking ways to make your production more eco-friendly, our team is ready to help you find the right solution for your specific needs.

We understand that every production line is unique, and that’s why we offer tailor-made solutions to meet the specific challenges faced by companies.

Our team will work closely with you to identify the most effective technology for your line, ensuring that you can achieve the highest levels of product safety while minimizing environmental impact.

Register for free with code 55J38

PACK EXPO is one of the most significant events of the year for the packaging industry, and the 2024 edition promises to be particularly exciting. An unmissable event for Claranor for several years. More information on the 2024 edition.

Our team will be pleased to welcome you to Stand N5972

Benjamin GUERIN

bguerin@claranor.com

Area Sales Manager

Anthony HERENG

ahereng@claranor.com

Commercial Director

Christophe RIEDEL

criedel@claranor.com

CEO

John PUTHOFF

john.puthoff@ims-spi.com

CEO