How to make sure your Claranor device is really performing and truly delivers the required level of decontamination in-line?

Not only do we regularly collaborate with independent laboratories such as Fraunhofer, INRA, or CNRS to validate our technology on a scientific basis, but we perform in-line testings in your premise to assure your operational efficiency.

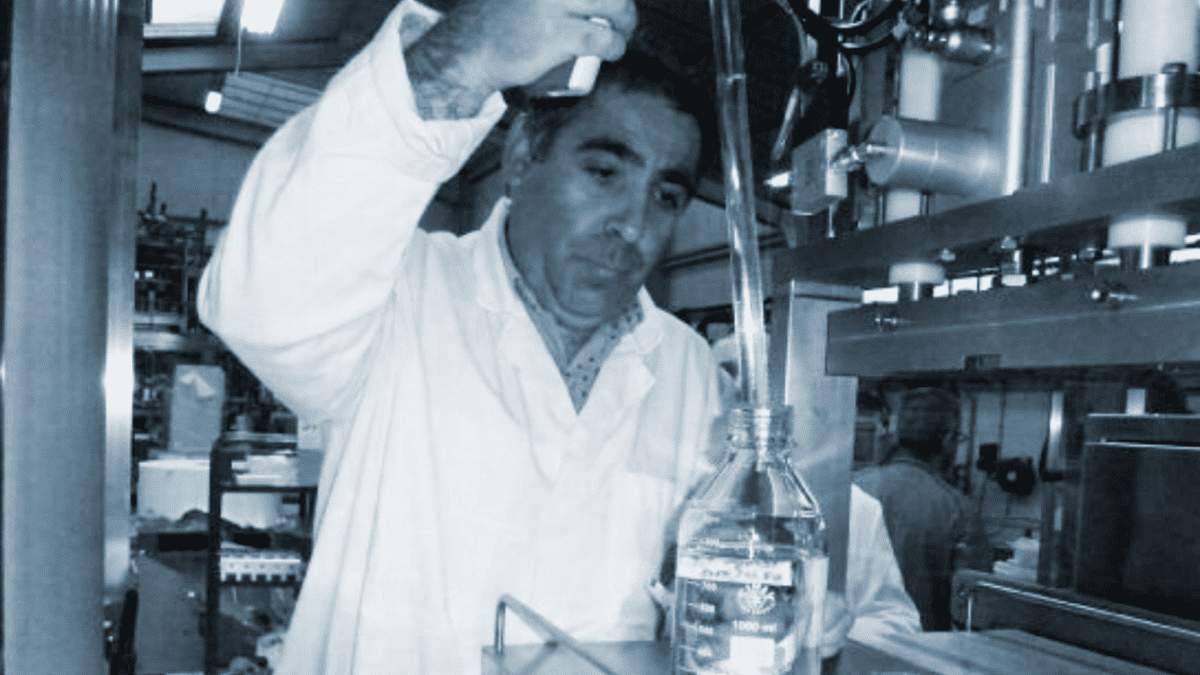

To ensure this, a Claranor microbiologist can perform a complete set of testings during operation, at the “the customer’s site to carry out the tests during operationMicrobiological Challenge Testing”.

The objective of the Microbiological Challenge Testing (MCT) :

Demonstrate the efficiency of the Pulsed light system unit installed on the filling line.

Perform the MCT in industrial conditions :

- proper running configuration, right nominal speed of the line

- meet the customer requirement in terms of the log-reduction of test micro-organism.

Principle of the MCT :

- Samples of packaging inoculated beforehand with the reference microorganism

- This packaging is placed on the line, under operating conditions, and treated by the Claranor Pulsed light equipment

- It is then removed from the line and analyzed, searching for residual microorganisms, in order to determine the log reduction obtained

Impartiality of the MCT :

The tests are carried out :

- With the assistance of an external laboratory for the inoculation of the packaging, and carrying out the analyses.

- Aligned with the VDMA (German Engineering Federation) recommendations.

- The tests must demonstrate the consistency of the results under operating conditions with those obtained under static conditions in the context of pre-sales tests.

Just another service offered to Claranor customers.

Database: effectiveness of pulsed light on caps and cups.

Claranor has compiled numerous results for commonly used packaging in a database accessible by simple request: Effectiveness of pulsed light on caps and cups.