Chemical-free decontamination: Claranor, a key partner for the dairy industry

In the demanding world of food processing, controlling food safety without compromising sustainability has become a central issue. In dairy products in particular, packaging decontamination is a critical step in preserving product quality and safety. For over 20 years, Claranor has been supporting leading dairy manufacturers with its water- and chemical-free Pulsed Light decontamination technology. Claranor cap decontamination machines have been around for 15 years. Claranor INNCAP Evolution is the latest innovation in the range.

A non-thermal, efficient and product-friendly process

Dairy products are sensitive products, subject to strict microbiological safety requirements. Traditional decontamination processes use chemicals such as peroxide, which require residue management, operator safety and effluent treatment.

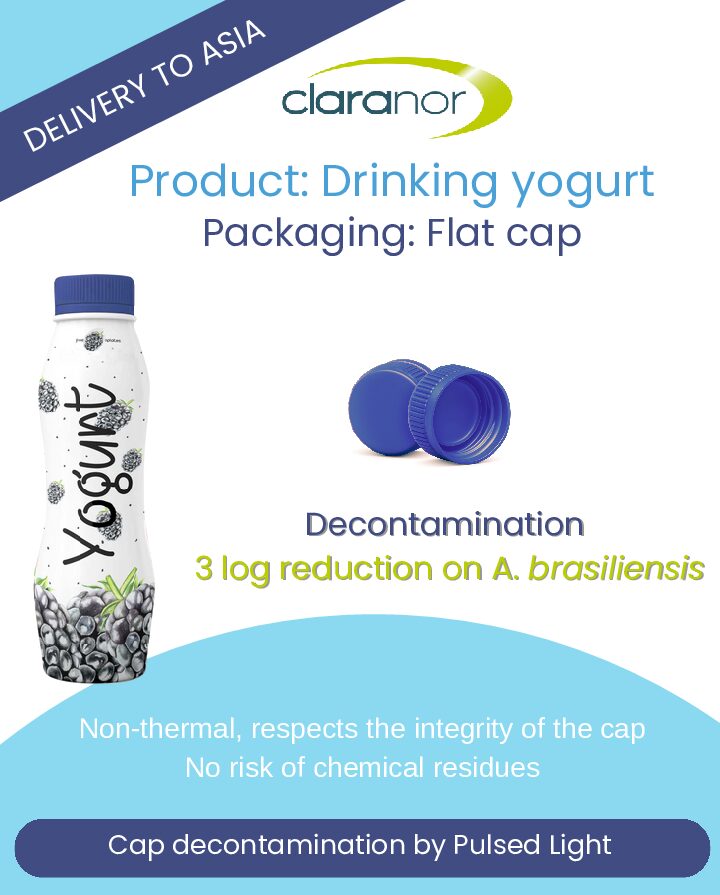

Claranor offers a simpler, cleaner alternative: Pulsed Light. This technology is based on very high-intensity light flashes capable of instantly destroying bacteria and mold. It enables non-thermal surface treatment, with no chemical residue.

Claranor, a benchmark player for dairy products

Since installing its first machine for dairy products at L’Armoricaine Laitière in partnership with Serac in 2010, Claranor has won over some of the world’s leading groups. Today, more than 140 plug decontamination machines are in service on dairy production lines around the world.

Thanks to its expertise in the field, Claranor has developed innovative, customized solutions to support manufacturers in their transition to more sustainable processes, while guaranteeing irreproachable product quality.

INNCAP Evolution: a machine designed for performance

Claranor’s INNCAP Evolution is specially designed for cap decontamination in high-speed environments. Compact, hygienic and easy to integrate into new or existing lines, it is suitable for flat and sport corks from 20 to 55 mm. Already installed in many countries, an INNCAP Evolution machine is being prepared for a 30,000-bph line in Asia.

Key benefits

- Instant processing, without preheating

- Speed rate up to 100,000 caps/hour

- Compact, hygienic design, with patented cabinet

- No water, no chemicals

- Low energy consumption

- Proven, customized results: 3-log reduction on Aspergillus brasiliensis

This machine offers a reliable, long-lasting solution that meets the expectations of manufacturers while simplifying their day-to-day operations.

Concrete benefits for manufacturers

For product quality

- No alteration of the closure that could affect product quality

- No chemical residues

- Preservation of microbiological integrity: no risk of cross-contamination

For the production line

- Easy to clean and integrate

- Closed process, safe for operators

- Zero corrosion, zero humidity

For the environment and operators

- No effluents

- No dangerous products to handle

- Low energy consumption

For profitability

- Low energy consumption

- Lower TCO than chemical decontamination methods

Claranor, a committed partner for more sustainable industry

For over 20 years, Claranor has been working alongside manufacturers to offer reliable, sober and scalable decontamination solutions. Building on its experience in the dairy sector, the company continues to innovate to meet market expectations for efficiency, compactness, safety and durability.

In addition to the range of sterilization machines dedicated to the dairy industry: machines for decontaminating cups, lids, caps, infant milk cans, bags and big bags, Claranor also offers a complete range of services. A team of itinerant technicians and customer service staff is on hand to support you throughout the machine’s lifetime. The offer includes a dedicated helpline, a support page with maintenance videos to make customers autonomous in the maintenance of their machine, preventive and corrective maintenance services as well as the supply of parts and consumables.

What if you moved into the light?

Claranor can help you with your new line or retrofit projects, in France and abroad. Choosing Pulsed Light means choosing a clean, proven technology.