EQUIPMENT FOR TRANSFERRING GOODS BETWEEN DIFFERENT HYGIENE LEVEL AREAS

INFANT FORMULA, MILK POWDER, SENSITIVE POWDERED FOOD & DRINKS

Decontamination rate :

> 3 log reduction on E.coli or C.sakazakii on flat surfaces of the bag

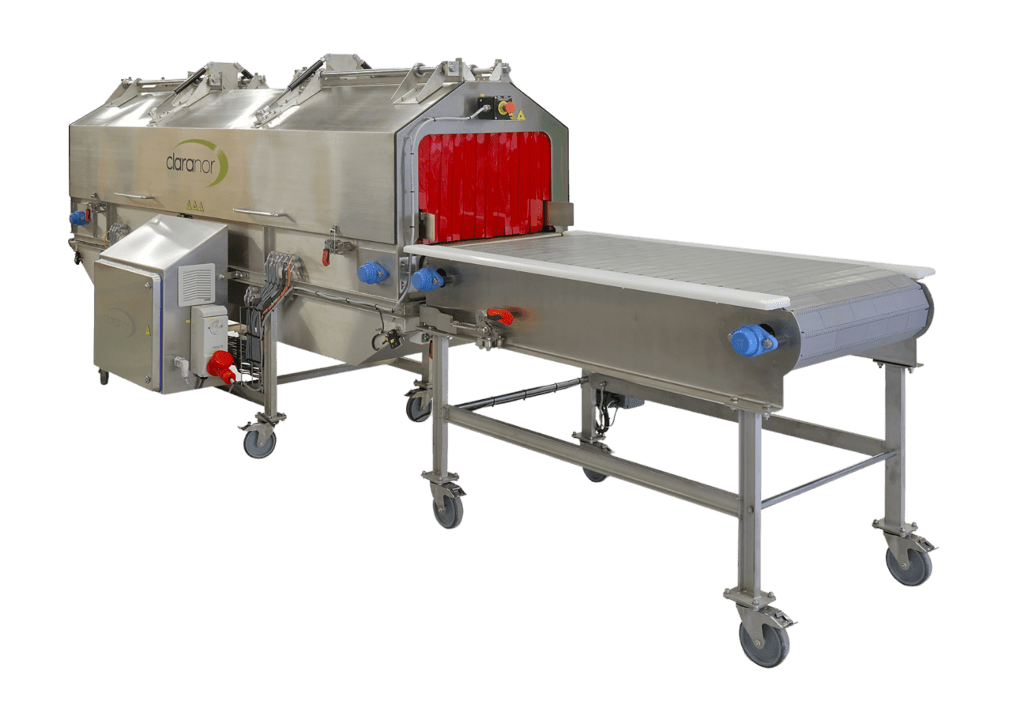

DECONTAMINATION TUNNEL

The treatment, dry and chemical-free, prevents cross-contamination.

Up to 120 bags/h

The sanitization tunnel allows decontamination of bulk packaging

moving from medium to high care production area.

- Hygienic design

- Respects product integrity

- Operator friendly, easy to operate, clean, and maintain

- To be installed at the interface of 2 different hygiene levels room

- Options: inlet/outlet conveyor, dedusting prior to treatment, panel screen/HMI on both sides

- Dimension: LENGTH (without conveyor): 2 650mm, WIDTH: 1 250mm

Maxi bag to be treated:

550 mm width, 900 mm long et 400 mm height

- Easy operation: synchronization with the production line

- Quick accesses for cleaning

- Low maintenance and ergonomics access for lamps change

Claranor design and engineering expertise allow you to benefit from a standard equipment tailored according to your specifications.

Claranor services provide you with full support: microbiological validation, commissioning, training, preventive and corrective maintenance.