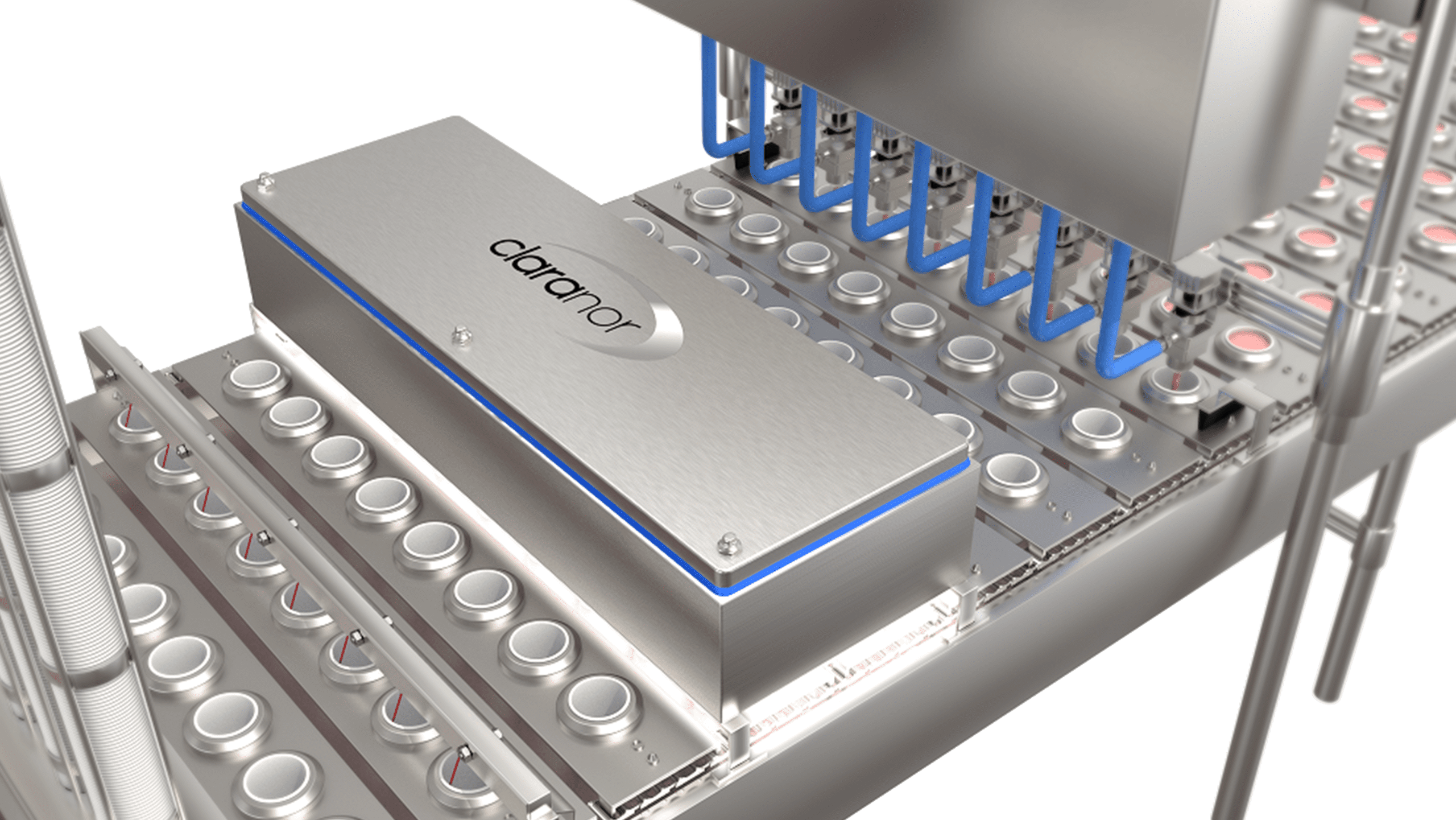

Since 2004, Claranor has been developing pulsed light sterilisation solutions for manufacturers, reconciling ecology and economy. In particular, the company designs and produces equipment for sterilising packaging using pulsed light for large groups in the food industry and more recently for the pharmaceutical and cosmetics industries.

A BDM building built in partnership with GSE

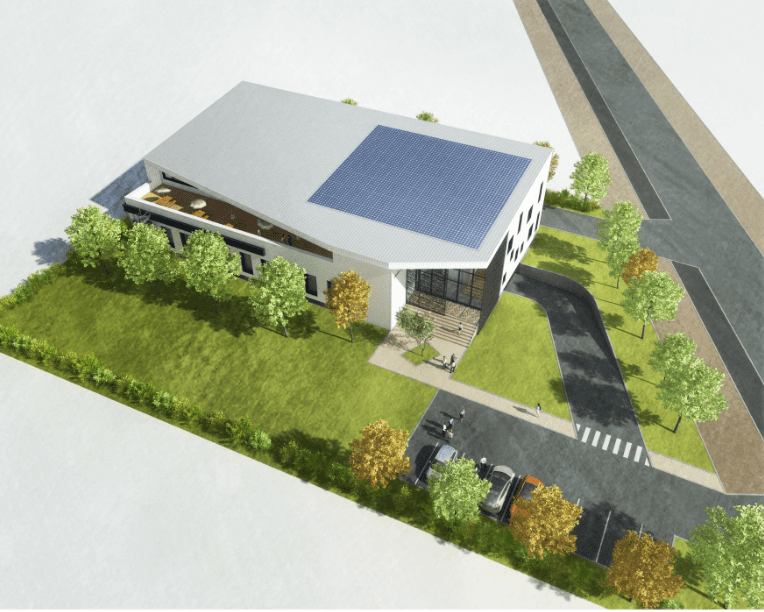

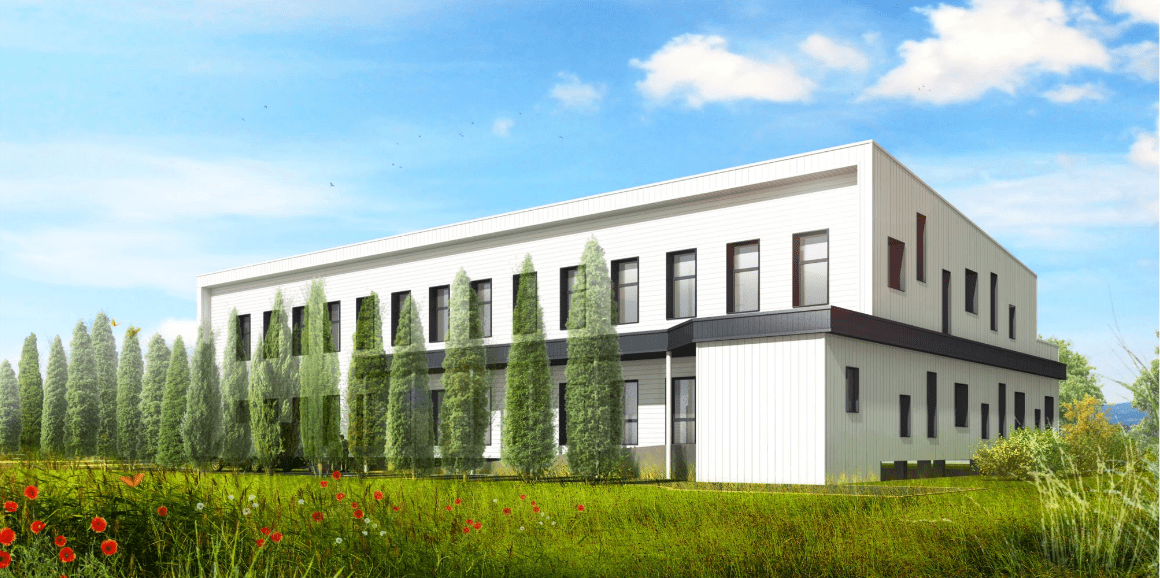

In an increasingly green approach, Claranor turns to GSE to imagine and build a sustainable and eco-responsible & eco-building: the BDM, a sustainable Mediterranean building corresponding to a French reference in terms of environmental quality

A green building in the Agroparc competitiveness pole

The new 1600m² building and head office will be located in the Agroparc technopole!

The design will focus on :

- Reducing the carbon footprint of materials: wooden structure and walls

- Energy performance: 100kWp of solar power

- Reducing the waterproofing of the ground: underground parking

- Comfort and health: atmospheric emissions of materials, noise protection, natural light, ambient temperature

Claranor was awarded BDM silver for its new construction in the areas of energy performance, carbon emission reduction and treatment of summer comfort.

About Claranor

Claranor is a world leader in Pulsed Light packaging sterilisation. Referenced by the main equipment manufacturers, Claranor equipment is today present in the largest industrial groups. In 2020, 450 packaging sterilization machines are in operation in 52 countries. Claranor holds 11 patents.

Since its creation in 2004, Claranor has developed a double expertise in packaging microbiology and industrialisation for the beverage and dairy industries.

This enables it to offer today standard or customised pulsed light sterilisation solutions.

The skills and know-how of its multidisciplinary team and its capacity for innovation are now attracting pharmaceutical and cosmetics manufacturers.