Equipment for production lines dedicated to sensitive products

Machine for cup and lid pulsed light decontamination

Refrigerated dairy dessert, DLC from 50 days (neutral products) to 60 days (acid products),

Yogurt, margarine, cream, cottage cheese, sauce, ready meal, drink …

Decontamination levels:

3 to 5 log reduction on microorganisms of reference

Cup decontamination

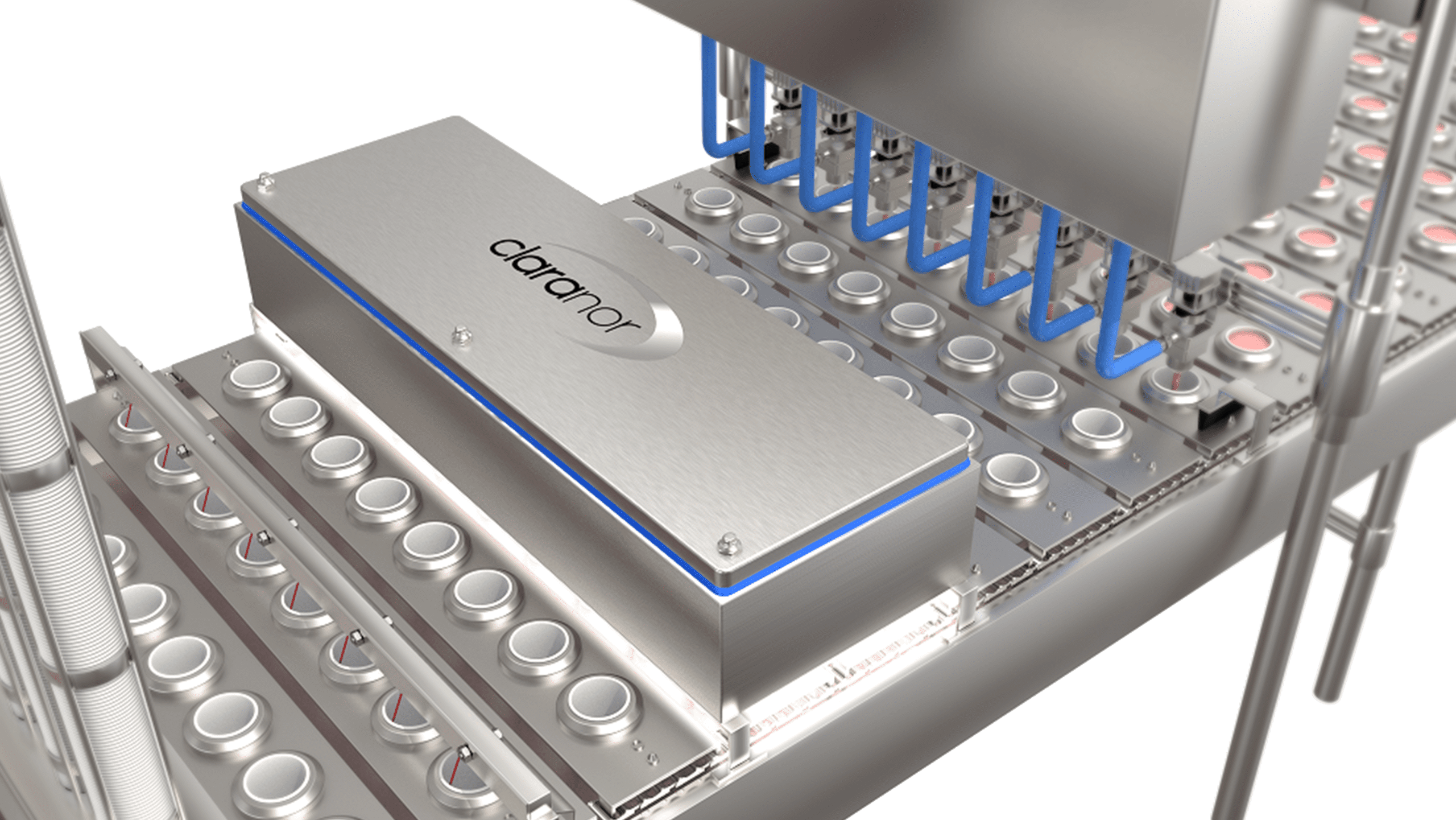

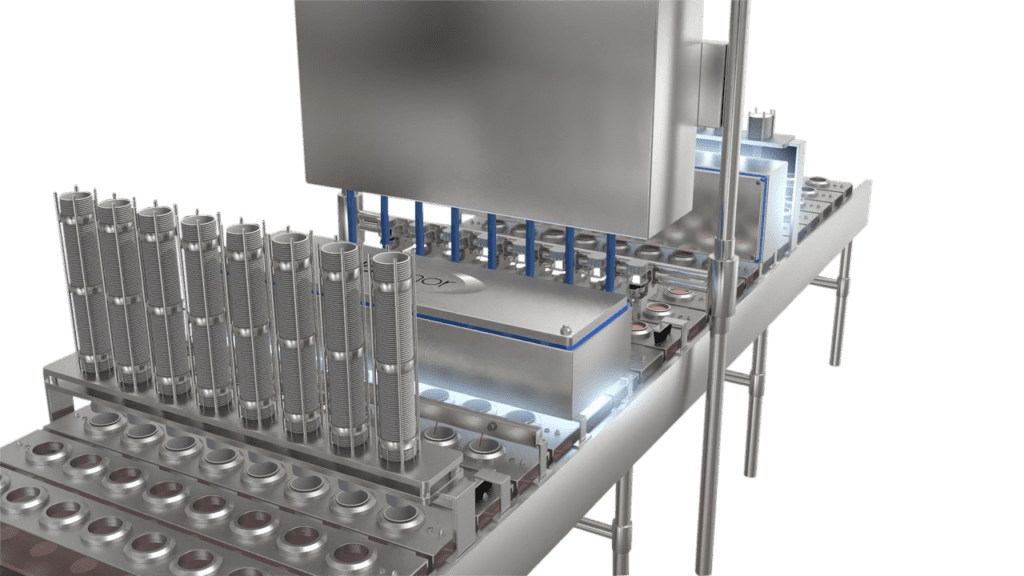

The Claranor online sterilization unit is integrated upstream of the filling

on 1 to 3 machine steps, 1 to 16 tracks.

Linear filler – rotary – on-the-fly processing

Up to 60 strokes / minute

Decontamination of the internal surface of the cup

All types of cups, trays, buckets, up to 20 kg including metal cans of infant milk.

Equipment integration can be done by Claranor

- Synchronization with the production line

- Instant processing

- Non thermal it respects the packaging

- No risk of chemical residues

- Economical and sustainable thanks to its very low energy consumption

FS lid decontamination

The Claranor online sterilization unit is integrated

in the lids distribution store.

Linear – rotary filler

up to 60 strokes / minute

Decontamination of the lid, surface in contact with the product.

All types and formats of aluminum and plastic sealing lids, pre-cut or reel

- Instant processing

- Non-thermal, it respects the packaging and the sealing properties of the seal

(no risk of deterioration or deformation) - No chemical residue

- Economical and sustainable thanks to its very low energy consumption

Puls’ DecontaminationCombi FS®

Ultra-clean line without chemical disinfectants

Linear filler – rotary – on-the-fly processing

Up to 60 strokes / minute

Decontamination of the internal surface of the cup

All types of cups, trays, buckets, up to 20 kg including metal cans of infant milk.

Equipment integration can be done by Claranor

- Synchronization with the production line

- Instant processing

- Non thermal it respects the packaging

- No risk of chemical residues

- Economical and sustainable thanks to its very low energy consumption