PULSED LIGHT STERILIZATION EQUIPMENT

TO BE INTEGRATED INTO NEW OR EXISTING FILLING LINES

Decontamination levels: 3 to 5 log reduction on reference germs

All our microbiological tests have been carried out in accordance with the VDMA’s recommendations

Packaging for beverages

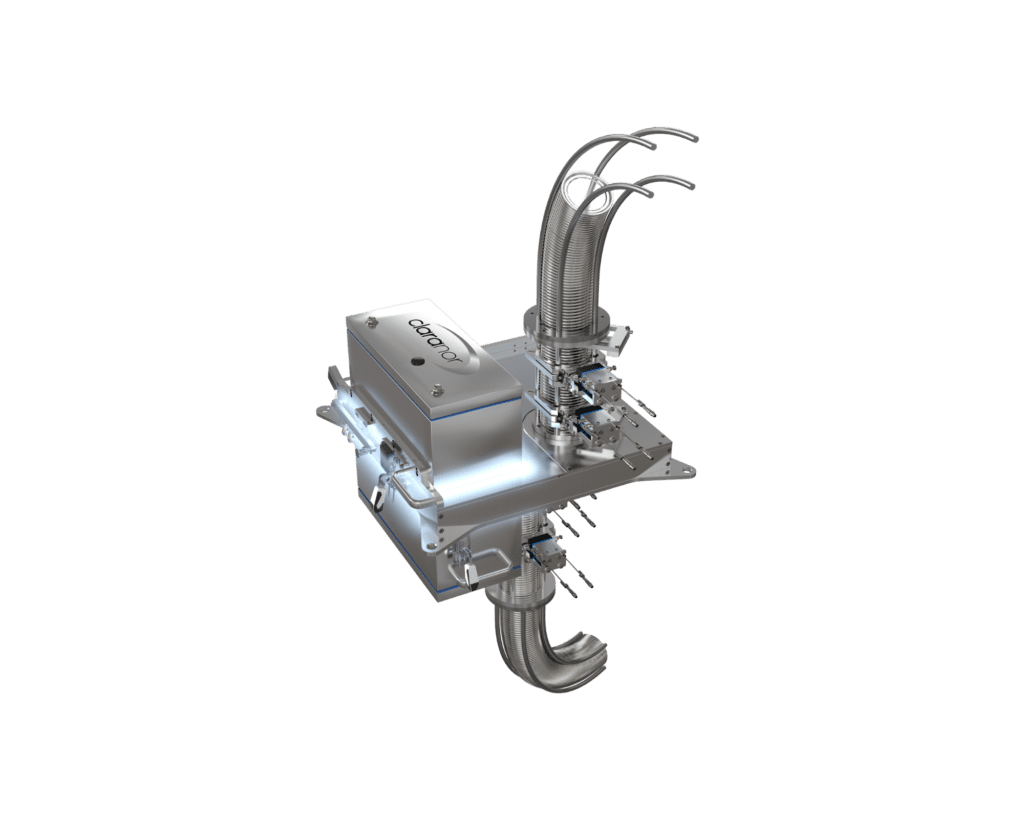

Decontamination by Pulsed Light

Closed loop water cooling

Can and can end

330 ml – Up to 360 cans/min

500 ml – Up to 240 cans/min

Pulsed light decontamination of the can and can end, surface in contact with the product, before filling and sealing the lid;

Adapted to Ultra-Clean Line without pasteurization tunnel.

Format Up to 500 ml alu can.

3 Log-Red on Aspergillus brasiliensis (VDMA Class IV )

Lid

Up to

16 000 lids/hour

Pulsed light decontamination of both sides of the lid: the surface in contact with the product or in contact with the aluminum lid, to avoid any risk of recontamination when re-staking.

Packaging for liquid product

Decontamination by Pulsed Light

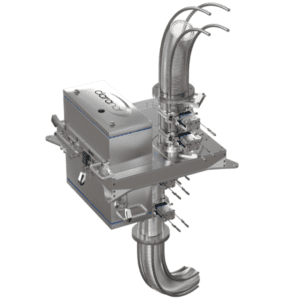

HIGH SPEED CAN

Up to 600 cans / minute

Microbiological decontamination of the inside of the can.

All types of metal or aluminum cans, all capacities.

The integration of the pulsed light sterilization equipment can be carried out by Claranor.

- Compact: 1 to 2 m

- Instant treatment, no preheating

- No water consumption

- Non-thermal, no heat generation in the working environment

- No chemical residues

- Economical and sustainable thanks to low energy consumption

- Reduced carbon footprint

LOW SPEED CAN

Up to 400 cans/minute

Microbiological decontamination of the inside of the can.

All types of metal or aluminum cans, all capacities.

The integration of the pulsed light sterilization equipment can be carried out by Claranor.

- Compact: 1 to 2 m

- Instant treatment, no preheating.

- Non-thermal, no heat release.

- No chemical residues.

- Economical and sustainable due to low energy consumption.

- No water consumption

ALU AND METAL LID

Up to 200 lids/minute

Microbiological decontamination of both sides of the lid to avoid recontamination during re-stacking

All types and sizes of aluminum and metal lids

- Lid unstacking and conveying equipment developed in partnership with Guylegall

- Instant processing

- No heating time

- All lids receive the same treatment

- Athermal

- No risk of chemical residues

- Economical and durable thanks to its very low energy consumption.

Packaging for infant powder milk

Decontamination by Low Pressure UV or Pulsed Light

Dry treatment, air cooling

Can and can end

Up to 400 cans/minute

Low Pressure UV decontamination of the can and can end, product contact surface, before filling and sealing the lid; without water.

Lid

Up to 16 000 lids/hour

Lid with or without integrated spoon

Pulsed light decontamination of the surface in contact with the product or in contact with the aluminium lid, to avoid any risk of recontamination when opening.